Stepper API Guide

Get started with your Stepper Motor Phidget

Quantity Available: 1000+

| Qty | Price |

|---|---|

| 10 | $95.00 |

| 25 | $85.00 |

| 50 | $75.00 |

| 100 | $70.00 |

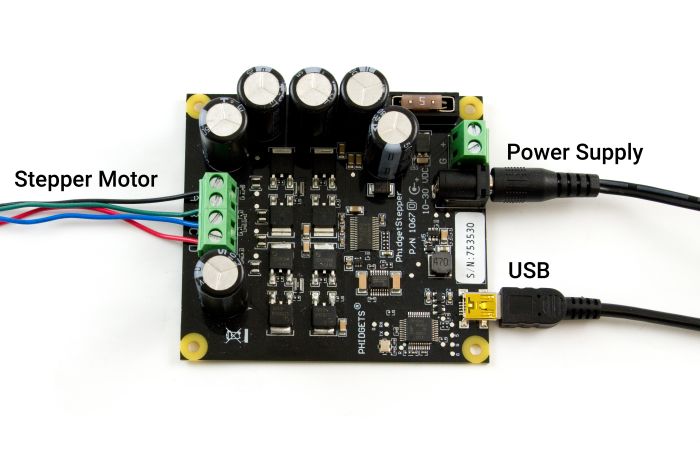

The PhidgetStepper Bipolar HC is a powerful stepper motor driver that operates on 10-30V DC and provides up to 4 amps of continuous current per phase to a single bipolar stepper motor.

This controller features two operating modes: Step Mode and Run Mode. In Step Mode, users set a Target Position, and the controller intelligently moves the motor toward the target while adhering to the user-specified Acceleration and Velocity Limit. In Run Mode, the controller continuously rotates the motor in the chosen direction, again following the defined Acceleration and Velocity Limit.

There are several built-in safety features, including over-current protection and polarity protection.

The PhidgetStepper Bipolar HC connects directly to a computer via USB.

| USB | This device connects directly to your computer, laptop or single-board computer. |

| Power Supply | An external power supply is required for this device (10-30VDC). |

| Stepper Motor | Connect a bipolar stepper motor to these inputs. |

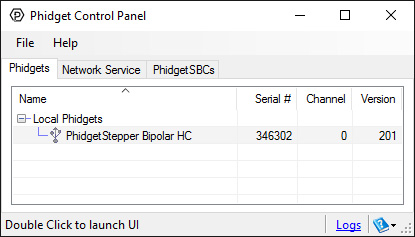

Use the Phidget Control Panel to explore your device's functionality. Each channel is described below.

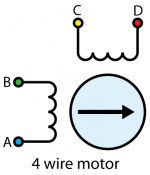

For the motors sold at Phidgets, you can simply wire the motor as follows:

If your motor has an unknown pinout, you can find out which wires share a coil by using a multimeter in resistance or conductivity mode.

If you want the default direction of rotation to be reversed, switch either the A and B or the C and D wires.

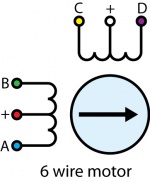

In a 6–wire bipolar motor, there are two + wires, one for each coil, which are the center taps for each coil. You will need to isolate which are the center tap wires and the corresponding wires for their coil.

These center taps are left unconnected when using the 1067. Check the datasheet for your motor to find out which wires are the center taps and connect the remaining wires as if it were a 4-wire motor.

If you don't know the pinout of your motor, you can use a multimeter to determine which wires belong to the same coil and which ones are the center taps. Use conductivity mode to determine which wires are connected to the same coil. Then, use resistance mode to check the values between each of the wires in the same coil. The center tap is the wire that has a lower resistance between the other wires.

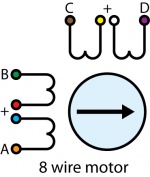

Check the datasheet for your motor to determine which wires belong the the same coil, and which coils are paired.

8 Wire Motors are very difficult to wire up if you do not have a schematic showing how the wires are connected to the internal coils. You can use a multimeter to determine which wires pair to the same coil, but you'll need to run the motor trial-and-error to determine which coil pairs with the other.

You can wire an 8-wire stepper in series or parallel. Series wiring will result in higher torque when the motor is stopped or at low speeds. Parallel wiring will provide better torque at higher speeds, but less torque overall. Since the current in parallel mode is split between two paths, the current rating is doubled.

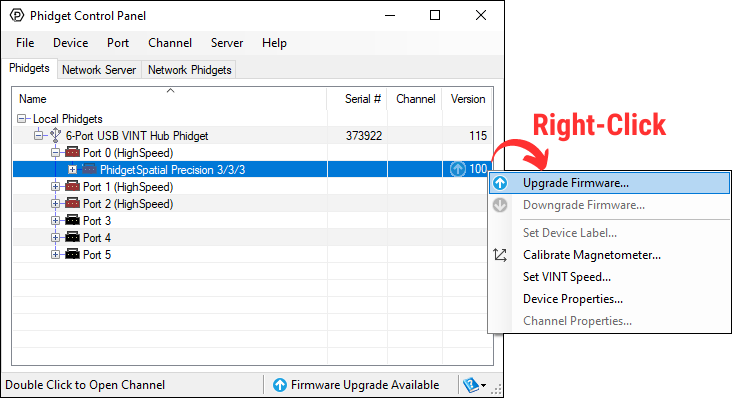

Firmware Upgrade

MacOS users can upgrade device firmware by double-clicking the device row in the Phidget Control Panel.

Linux users can upgrade via the phidget22admin tool (see included readme for instructions).

Windows users can upgrade the firmware for this device using the Phidget Control Panel as shown below.

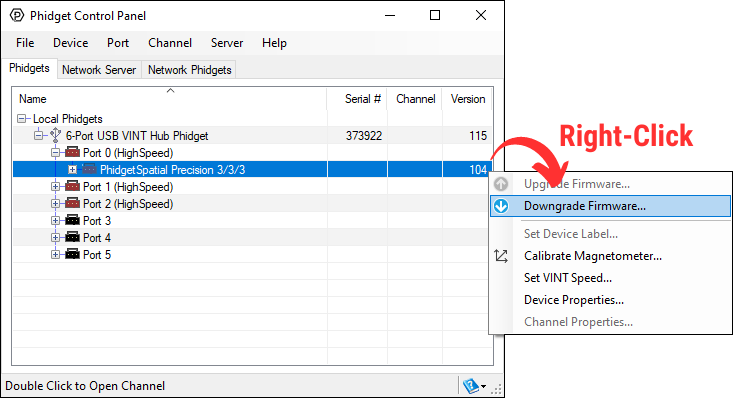

Firmware Downgrade

Firmware upgrades include important bug fixes and performance improvements, but there are some situations where you may want to revert to an old version of the firmware (for instance, when an application you're using is compiled using an older version of phidget22 that doesn't recognize the new firmware).

MacOS and Linux users can downgrade using the phidget22admin tool in the terminal (see included readme for instructions).

Windows users can downgrade directly from the Phidget Control Panel if they have driver version 1.9.20220112 or newer:

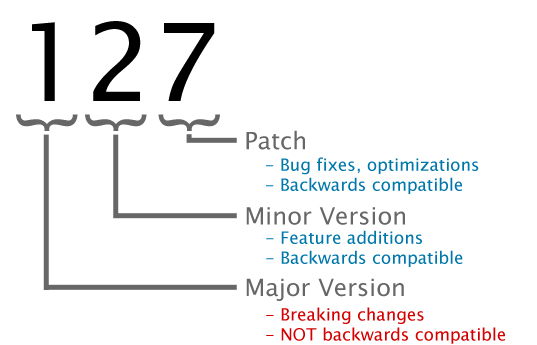

Firmware Version Numbering Schema

Phidgets device firmware is represented by a 3-digit number. For firmware patch notes, see the device history section on the Specifications tab on your device's product page.

| Controller Properties | |

|---|---|

| API Object Name | Stepper |

| Motor Type | Bipolar Stepper |

| Number of Motor Ports | 1 |

| Motor Position Resolution | 1⁄16 Step (40-Bit Signed) |

| Position Max | ± 1E+15 1⁄16 steps |

| Stepper Velocity Resolution | 1 1⁄16 steps/sec |

| Stepper Velocity Max | 250000 1⁄16 steps/sec |

| Stepper Acceleration Resolution | 1 1⁄16 steps/sec² |

| Stepper Acceleration Min | 2 1⁄16 steps/sec² |

| Stepper Acceleration Max | 1E+07 1⁄16 steps/sec² |

| Board Properties | |

| Controlled By | USB (Mini-USB) |

| USB Stack | HID |

| Driver Support | Phidget21, Phidget22 |

| API Object Name | Stepper |

| Electrical Properties | |

| Available Current per Coil Max | 4 A |

| Supply Voltage Min | 10 V DC |

| Supply Voltage Max | 30 V DC |

| Current Consumption Min | 25 mA |

| USB Speed | Full Speed |

| Replacement Fuse | 5A Slow Blow Blade Type, Regular or Micro |

| Isolation Voltage (DC) | 3.8 kV DC |

| Physical Properties | |

| Power Jack | 5.5 x 2.1mm Center Positive |

| Recommended Wire Size (Motor Terminal) | 12 to 26 AWG |

| Recommended Wire Size (Power Terminal) | 12 to 26 AWG |

| Operating Temperature Min | -20 °C |

| Operating Temperature Max | 85 °C |

| Customs Information | |

| Canadian HS Export Code | 8471.80.00 |

| American HTS Import Code | 8471.80.40.00 |

| Country of Origin | CN (China) |

| Date | Board Revision | Device Version | Packaging Revision | Comment |

|---|---|---|---|---|

| January 2013 | 0 | 200 | Product Release | |

| October 2015 | 0 | 201 | OS X El Capitan USB fix | |

| April 2017 | 0 | 202 | Changes to USB-stack | |

| October 2017 | 0 | 202 | B | Removed USB cable |

| October 2018 | 0 | 203 | B |

|

| November 2019 | 0 | 204 | B | Fixed bug affecting 'stopped' event while changing position during deceleration |

| October 2020 | 0 | 205 | B | Fixed an issue causing the timer to count over the match register |

| November 2020 | 0 | 206 | B | Fixed crash that could occur at low acceleration |

| Channel Name | API | Channel |

|---|---|---|

| Bipolar Stepper Controller | Stepper | 0 |

The 1067 can control both unipolar and bipolar motors, but in almost all cases you're better off with a bipolar motor due to their increased power and more precise step angles. If you care about torque, large motors with high gear ratios are your best bet. If you car about speed, motors with no gearbox and high step angles are better. If you want precision, steppers without gearboxes and low step angles are best because while gearboxes do result in smaller steps, they also introduce a flat 1-3 degrees of positional error due to backlash in the gears.

| Product | Motor Properties | Electrical Properties | Physical Properties | Gearbox Properties | ||||

|---|---|---|---|---|---|---|---|---|

| Part Number | Price | Step Angle | Rated Torque | Maximum Motor Speed | Recommended Voltage | Shaft Diameter | Weight | Gear Ratio |

NEMA11 - 1.8 Degree - 0.67A Stepper - Gearless

|

$16.00 | 1.8° | 520 g·cm | 1300 RPM | 24 V DC | 5 mm | 111.4 g | — |

NEMA11 - 1.8 Degree - 1.5A Stepper - 27:1 Gearbox

|

$38.00 | 1.8° | 14 kg·cm | 50 RPM | 24 V DC | 6 mm | 217.5 g | 26 103⁄121 : 1 |

NEMA11 - 1.8 Degree - 1.5A Stepper - 100:1 Gearbox

|

$50.00 | 1.8° | 32 kg·cm | 13 RPM | 24 V DC | 6 mm | 243.6 g | 99 1044⁄2057 : 1 |

NEMA14 - 1.8 Degree - 1A Stepper - Gearless

|

$16.00 | 1.8° | 1.2 kg·cm | 1000 RPM | 24 V DC | 5 mm | 200 g | — |

NEMA17 - 0.9 Degree - 1.68A Stepper - Gearless

|

$20.00 | 0.9° | 3.3 kg·cm | 400 RPM | 24 V DC | 5 mm | 288 g | — |

NEMA17 - 1.8 Degree - 1.68A Stepper - Gearless

|

$16.00 | 1.8° | 3.3 kg·cm | 1000 RPM | 24 V DC | 5 mm | 289 g | — |

NEMA17 - 1.8 Degree - 1.68A Stepper - 5.18:1 Gearbox

|

$40.00 | 1.8° | 18 kg·cm | 200 RPM | 24 V DC | 8 mm | 457 g | 5 2⁄11 : 1 |

NEMA17 - 1.8 Degree - 1.68A Stepper - 14:1 Gearbox

|

$42.00 | 1.8° | 30 kg·cm | 70 RPM | 24 V DC | 8 mm | 502 g | 13 212⁄289 : 1 |

NEMA17 - 1.8 Degree - 1.68A Stepper - 27:1 Gearbox

|

$44.00 | 1.8° | 30 kg·cm | 40 RPM | 24 V DC | 8 mm | 503 g | 26 103⁄121 : 1 |

NEMA17 - 1.8 Degree - 1.68A Stepper - 51:1 Gearbox

|

$46.00 | 1.8° | 48 kg·cm | 20 RPM | 24 V DC | 8 mm | 564 g | 50 4397⁄4913 : 1 |

NEMA17 - 1.8 Degree - 1.68A Stepper - 100:1 Gearbox

|

$48.00 | 1.8° | 48 kg·cm | 10 RPM | 24 V DC | 8 mm | 564 g | 99 1044⁄2057 : 1 |

NEMA23 - 0.9 Degree - 2.8A Stepper - Gearless

|

$28.00 | 0.9° | 11.2 kg·cm | 500 RPM | 24 V DC | 1⁄4″ | 695 g | — |

NEMA23 - 1.8 Degree - 2.8A Stepper - 4.25:1 Gearbox

|

$70.00 | 1.8° | 46.6 kg·cm | 165 RPM | 24 V DC | 12 mm | 1.2 kg | 4 1⁄4 : 1 |

NEMA23 - 1.8 Degree - 2.8A Stepper - 15:1 Gearbox

|

$72.00 | 1.8° | 150 kg·cm | 50 RPM | 24 V DC | 12 mm | 1.3 kg | 15 3⁄10 : 1 |

NEMA23 - 1.8 Degree - 2.8A Stepper - 77:1 Gearbox

|

$74.00 | 1.8° | 240 kg·cm | 10 RPM | 24 V DC | 12 mm | 1.5 kg | 76 49⁄64 : 1 |

NEMA34 - 1.8 Degree - 4A Stepper - Gearless

|

$60.00 | 1.8° | 30 kg·cm | 200 RPM | 30 V DC | 12 mm | 1.8 kg | — |

This Phidget requires a power supply between 10 and 30V DC. We recommend that you use a 12V DC power supply for small steppers and a 24V DC supply for larger ones. If you're not sure, check the data sheet for your motor for the recommended power supply voltage (not to be confused with the coil voltage, which is usually much lower). For best results, we recommend getting a 5 amp supply. Select the power supply from the list below that matches your region's wall socket type.

| Product | Electrical Properties | Physical Properties | ||

|---|---|---|---|---|

| Part Number | Price | Power Supply Current | Output Voltage | Wall Plug Style |

Power Supply 24VDC 14.6A

|

$40.00 | 14.6 A | 24 V | — |

Power Supply 24VDC 25A Current Limiting

|

$120.00 | 25 A | 24 V | — |

Power Supply 12VDC 0.5A - EU

|

$1.50 | 500 mA | 12 V | European |

Power Supply 12VDC 0.5A - US

|

$1.50 | 500 mA | 12 V | North American |

Power Supply 12VDC 2.0A - AU

|

$10.00 | 2 A | 12 V | Australian |

Power Supply 12VDC 2.0A - EU

|

$10.00 | 2 A | 12 V | European |

Power Supply 12VDC 2.0A - UK

|

$10.00 | 2 A | 12 V | British |

Power Supply 12VDC 5A

|

$20.00 | 5 A | 12 V | — |

Power Supply 24VDC 1.0A - US

|

$10.00 | 1 A | 24 V | North American |

Power Supply 24VDC 2.5A

|

$20.00 | 2.5 A | 24 V | — |

Power Supply 24VDC 5A

|

$40.00 | 5 A | 24 V | — |

Power Supply-12VDC 2.0A - US

|

$10.00 | 2 A | 12 V | North American |

The PhidgetStepper Bipolar HC comes with a 5 amp automotive fuse.

Use a USB cable to connect this Phidget to your computer. We have a number of different lengths available, although the maximum length of a USB cable is 5 meters due to limitations in the timing protocol. For longer distances, we recommend that you use a Single Board Computer to control the Phidget remotely.

| Product | Physical Properties | |||

|---|---|---|---|---|

| Part Number | Price | Connector A | Connector B | Cable Length |

USB-A to Mini-B Cable 28cm 24AWG

|

$3.00 | USB Type A | USB Mini-B | 280 mm |

USB-A to Mini-B Cable 28cm Right Angle

|

$3.50 | USB Type A | USB Mini-B (90 degree) | 280 mm |

USB-A to Mini-B Cable 60cm 24AWG

|

$3.50 | USB Type A | USB Mini-B | 600 mm |

USB-A to Mini-B Cable 83cm Right Angle

|

$4.50 | USB Type A | USB Mini-B (90 degree) | 830 mm |

USB-A to Mini-B Cable 120cm 24AWG

|

$4.00 | USB Type A | USB Mini-B | 1.2 m |

USB-A to Mini-B Cable 180cm 24AWG

|

$4.00 | USB Type A | USB Mini-B | 1.8 m |

USB-A to Mini-B Cable 450cm, 20 AWG 2C

|

$12.00 | USB Type A | USB Mini-B | 4.5 m |

USB-C to Mini-B Cable 60cm 24AWG

|

$5.00 | USB Type C | USB Mini-B | 600 mm |

USB-C to Mini-B Cable 180cm 24AWG

|

$6.00 | USB Type C | USB Mini-B | 1.8 m |

| Product | Controller Properties | Electrical Properties | |||

|---|---|---|---|---|---|

| Part Number | Price | Motor Position Resolution | Stepper Velocity Resolution | Stepper Velocity Max | Available Current per Coil Max |

4A Stepper Phidget

|

$50.00 | 1⁄16 Step (40-Bit Signed) | 1 1⁄16 steps/sec | 115000 1⁄16 steps/sec | 4 A |

8A Stepper Phidget

|

$90.00 | 1⁄16 Step (40-Bit Signed) | 1 1⁄16 steps/sec | 115000 1⁄16 steps/sec | 8 A |

PhidgetStepper Bipolar HC

|

$100.00 | 1⁄16 Step (40-Bit Signed) | 1 1⁄16 steps/sec | 250000 1⁄16 steps/sec | 4 A |