Replaced by the 3340_0, the same motor with a rear shaft and encoder mounting holes.

This motor is a larger NEMA-17 motor that produces a whopping 4800g-cm of holding torque and fine resolution. The motor is also very efficient in converting current into torque and velocity.

| Motor Properties | |

|---|---|

| Motor Type | Bipolar Stepper |

| Manufacturer Part Number | 42BYGHM810 |

| Step Angle | 0.9° |

| Step Accuracy | 5 % |

| Holding Torque | 4.8 kg·cm |

| Rated Torque | 4.3 kg·cm |

| Maximum Speed (w/1063 Motor Controller) | 300 RPM |

| Maximum Motor Speed | 2344 RPM |

| Acceleration at Max Speed (w/1067 Motor Controller) |

2.4E+06 1⁄16 steps/sec² |

| Electrical Properties | |

| Recommended Voltage | 12 V DC |

| Rated Current | 2.4 A |

| Coil Resistance | 1 Ω |

| Phase Inductance | 1.8 mH |

| Physical Properties | |

| Shaft Diameter | 5 mm |

| Mounting Plate Size | NEMA - 17 |

| Weight | 362 g |

| Number of Leads | 4 |

| Wire Length | 300 mm |

| Customs Information | |

| Canadian HS Export Code | 8501.10.00 |

| American HTS Import Code | 8501.10.40.60 |

| Country of Origin | CN (China) |

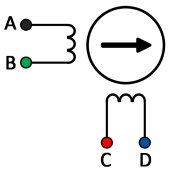

The 3302 stepper motor connects to a bipolar motor controller such as the 1067 - PhidgetStepper Bipolar HC.

The following diagram shows how to connect the motor wires to the board connectors to produce a clockwise rotation in the stepper motor when increasing position. To wire for counter-clockwise rotation when increasing position, reverse the red and blue wires.

Note: Make sure to unplug the power cord from the motor controller before switching wires around.

|

Connecting the motor directly to a power supply will destroy the motor and void the warranty. If you want to check your motor make sure it is connected to a constant current / chopper drive controller. |

The mounting holes on this motor are compatible with the 3338 - Mounting Bracket (NEMA17).