4-20mA Sensor Interface Guide

|

Introduction

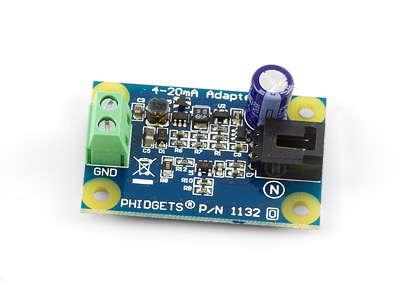

A 4-20mA sensor interface is a small device that adapts a 2-wire 4-20mA sensor's output to an analog output.

Normally, 4-20mA sensors are intended for industrial use and are difficult to use with a computer. However, with a 4-20mA sensor interface and a Phidgets Interface Kit (or any device with an Analog Input), these sensors can be used as easily as an ordinary analog sensor.

How it works

Before understanding what the 4-20mA sensor interface does, it's useful to know how a 4-20mA sensor is different from an analog sensor.

4-20mA Sensors

4-20mA is an electrical standard for connecting sensors to a data acquisition device (DAQ). A 4-20mA sensor has two wires. One wire is used to power the sensor, and the other is a ground. The sensor sends data to the DAQ in the form of the amount of current it consumes. For example, a 4-20mA velocity sensor would consume 4mA when it is sensing zero movement, and would output 20mA when the sensor is moving at the maximum velocity it can sense. Is the relationship linear? Can it be assumed that a value of 12mA corresponds to exactly half of the sensor's max? 4-20mA sensors are usually expensive and intended for industrial purposes. There are often less expensive 0-5V analog versions available.

Advantages of a 4-20mA Sensor:

- You can use longer wires with a 4-20mA sensor, since the data values are sent in the form of current rather than voltage levels that drop off with distance. However, you should ensure that the minimum voltage required to power the sensor is present at the end of the wire. To check, use a multimeter to measure the voltage across the two wires connecting to the sensor, when the sensor is measuring it's maximum value (and therefore drawing close to 20mA of current). If the voltage is higher than the minimum required voltage of the sensor (found in the sensor's data sheet), then it should be fine. Please note that twisted pair wire is the best for these long wire applications.

- 4-20mA sensors are less susceptible to electromagnetic interference (EMI) . This is because the data is sent in the form of current, which is less susceptible to EMI than voltage.

- It is easier to tell when your system has failed with a 4-20mA sensor. When a 4-20mA sensor senses its minimum value, it consumes 4mA of current. If it ever consumes zero current, it usually means there is a broken wire or some other failure in the system. When a 0-5V sensor fails in this way, the data line would read zero volts, which could mean it's just sensing zero.

Disadvantages of a 4-20mA Sensor:

- Usually more expensive than 0-5V analog sensors

- 4-20mA sensors are not very efficient, because they only need 4mA to function, and any additional current draw exists solely to communicate the value it is sensing.

When to use a 4-20mA Sensor:

- If you already own a 4-20mA sensor and don't want to buy an analog version

- You need to use a very long wire between the sensor and the power source

- The environment has a lot of electromagnetic interference

- The sensor is only available in the 4-20mA format

4-20mA Sensor Interface

Now that we've covered how a 4-20mA sensor is different from a 0-5V analog sensor, the basic operation of a 4-20mA sensor interface should be clear. It simply powers the sensor and monitors the current consumption on the power line. It then converts the 4-20mA value to a 0-5V analog signal at its output.

Basic Use

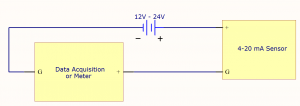

(diagram)

Using a 4-20mA sensor interface with Phidgets is very simple. Simple connect the positive wire of the sensor to the +15V output on the 4-20mA interface, and connect the ground wire of the sensor to the ground wire of the interface. Then, the analog output of the 4-20mA interface can be read by any interface kit with an analog input, which can send the value to your computer via USB. Check the sensor's data sheet to determine how your program should interpret the data it is receiving.

Using a 24V 4-20mA Sensor with Phidgets

(diagram)

The Phidgets 4-20mA interface can only supply the sensor with 15V. If you need to use a 24V sensor, you can still use a 4-20mA interface as long as you have an external 24V power supply. Connect the wires as shown in the diagram. The +15V terminal of the 4-20mA interface remains unused, but don't worry, the interface won't draw power that it doesn't need.

How to choose

- What are the parameters for deciding which product to buy?

- If a customer called and wanted to know which product to buy you would initially ask "What do you want this for?" Build this section as if you were continuing to ask the further questions you would need to help the customer decide what to buy. Help them figure what product to buy/why buy the product without them actually having to call us.

Types or Classes

- Analyse commonalities of the product family and categorize the individual products into the classes

- There should be very few products with exceptions.

- Explain the distinguishing parameter for each class of product

- Explain the differences between each class and all the other classes.

- Make sure the class distinctions are different enough- and only split classes for characteristics that are important enough

- This section should assist the customer in making their selection criteria easier to determine.

Conclusion

- Much the same as the Introduction, but using reference to supplied information to justify the statements.

How to buy

- Table of products, divided into classes discussed above, and individually linked

- This section could be auto-generated eventually

Things this page should cover:

4-20 mA sensors:

- 4-20 mA is an electrical standard for connection sensors to a data acquisition device.

- 2 wires are used, one wire to power the sensor and the other wire is a"ground".

- The sensor sends data by changing the amount of current it consumes

- This is not very efficient, but it is much more immune to noise, and can be used for long distances between sensor an DAQ.

- 4-20 mA sensors often run off high voltages, often 12-24v but check sensor data sheet to be sure

- 4-20 mA sensors are typically expensive and industrial. There are often 0-5v versions available.

- Why to use 4-20mA sensors?

- You have one already

- You want to do a really long run of wire

- Environment has lots of EMI

- Sensor is only available in 4-20 mA format

Advantages:

- If wire is broken, no current is consumed (sensor returns 0 A), normal operation is minimum 4mA, therefore failure is obvious.

- Q: the Phidget 4-20 mA adapter can only supply 15V? What if my sensor needs 24V?

- A: Use 24v external power supply, hook + side to sensor and - side to ground on 1018. The 15V on the 1132 is left unused.

- Remember: on very long wire runs, you may lose too much voltage on the wire. The minimum varies by sensor; check the datasheet.

to measure the effective voltage, use a multimeter across the two wires close to the sensor, when the sensor is returning a large current (as close to 20mA as possible)

- Twisted pair wire is best for long-wire applications