4-20mA Sensor Interface Guide: Difference between revisions

No edit summary |

|||

| (43 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

{{#seo:|description=Learn the basics about 4-20mA sensors with this guide. This includes: how they work, advantages and disadvantages, and when to consider using these sensors.}} | |||

{{#seo:|keywords=4-20mA}} | |||

[[Category:IntroGuide]] | |||

__TOC__ | |||

==Introduction== | ==Introduction== | ||

[[Image:DAQ1400_0.jpg|400px|right|link=]] | |||

Normally, 4-20mA sensors are intended for industrial use, and are difficult to use with a computer. However, with a {{CT|420Adapter|4-20mA adapter Phidget}}, interfacing with these sensors is extremely simple. | |||

Normally, 4-20mA sensors are intended for industrial use and are difficult to use with a computer. | <br clear=all> | ||

However, with a 4-20mA | |||

==How it works== | ==How it works== | ||

===Overview=== | |||

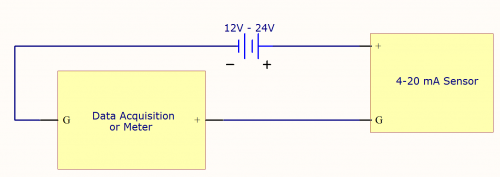

[[Image:420Interface.png|500px|link=|thumb|Traditional setup for reading a 4-20mA sensor.]] | |||

4-20mA is an electrical standard for connecting sensors to a ''data acquisition device'' (DAQ). A 4-20mA sensor has two wires. One wire is used to power the sensor, and the other is a ground. The sensor sends data to the DAQ in the form of the amount of current it consumes. For example, a 4-20mA velocity sensor might consume 4mA when it is sensing zero movement, and would output 20mA when the sensor is moving at the maximum velocity it can sense. 4-20mA sensors are usually expensive and intended for industrial purposes. There are often less expensive 0-5V analog versions available. | |||

===Advantages of a 4-20mA Sensor=== | |||

*You can use longer wires with a 4-20mA sensor, since the data values are sent in the form of current rather than voltage levels that drop off with distance. However, you should ensure that the minimum voltage required to power the sensor is present at the end of the wire. To check, use a multimeter to measure the voltage across the two wires connecting to the sensor, when the sensor is measuring it's maximum value (and therefore drawing close to 20mA of current). If the voltage is higher than the minimum required voltage of the sensor (found in the sensor's data sheet), then it should be fine. Please note that twisted pair wire is the best for these long wire applications. | |||

*4-20mA sensors are less susceptible to electromagnetic interference (EMI). This is because the data is sent in the form of current, which is less susceptible to EMI than voltage. | |||

*It is easier to tell when your system has failed with a 4-20mA sensor. When a 4-20mA sensor senses its minimum value, it consumes 4mA of current. If it ever consumes zero current, it means there is a broken wire or some other failure in the system. When a 0-5V sensor fails in this way, the data line would read zero volts, which could mean it's just sensing zero. | |||

===Disadvantages of a 4-20mA Sensor=== | |||

=== | * Usually more expensive than 0-5V sensors. | ||

* 4-20mA sensors are not very efficient, because they only need 4mA to function, and any additional current draw exists solely to communicate the value it is sensing | |||

* | ===When to use a 4-20mA Sensor=== | ||

* If you already own a 4-20mA sensor and don't want to buy an analog version. | |||

* You need to use a very long wire between the sensor and the power source. | |||

* The environment has a lot of electromagnetic interference. | |||

* The sensor is only available in the 4-20mA format. | |||

* | |||

* | |||

= | |||

* 4- | |||

* | |||

* | |||

* | |||

Latest revision as of 20:10, 26 June 2023

Introduction

Normally, 4-20mA sensors are intended for industrial use, and are difficult to use with a computer. However, with a 4-20mA adapter Phidget, interfacing with these sensors is extremely simple.

How it works

Overview

4-20mA is an electrical standard for connecting sensors to a data acquisition device (DAQ). A 4-20mA sensor has two wires. One wire is used to power the sensor, and the other is a ground. The sensor sends data to the DAQ in the form of the amount of current it consumes. For example, a 4-20mA velocity sensor might consume 4mA when it is sensing zero movement, and would output 20mA when the sensor is moving at the maximum velocity it can sense. 4-20mA sensors are usually expensive and intended for industrial purposes. There are often less expensive 0-5V analog versions available.

Advantages of a 4-20mA Sensor

- You can use longer wires with a 4-20mA sensor, since the data values are sent in the form of current rather than voltage levels that drop off with distance. However, you should ensure that the minimum voltage required to power the sensor is present at the end of the wire. To check, use a multimeter to measure the voltage across the two wires connecting to the sensor, when the sensor is measuring it's maximum value (and therefore drawing close to 20mA of current). If the voltage is higher than the minimum required voltage of the sensor (found in the sensor's data sheet), then it should be fine. Please note that twisted pair wire is the best for these long wire applications.

- 4-20mA sensors are less susceptible to electromagnetic interference (EMI). This is because the data is sent in the form of current, which is less susceptible to EMI than voltage.

- It is easier to tell when your system has failed with a 4-20mA sensor. When a 4-20mA sensor senses its minimum value, it consumes 4mA of current. If it ever consumes zero current, it means there is a broken wire or some other failure in the system. When a 0-5V sensor fails in this way, the data line would read zero volts, which could mean it's just sensing zero.

Disadvantages of a 4-20mA Sensor

- Usually more expensive than 0-5V sensors.

- 4-20mA sensors are not very efficient, because they only need 4mA to function, and any additional current draw exists solely to communicate the value it is sensing

When to use a 4-20mA Sensor

- If you already own a 4-20mA sensor and don't want to buy an analog version.

- You need to use a very long wire between the sensor and the power source.

- The environment has a lot of electromagnetic interference.

- The sensor is only available in the 4-20mA format.